Laminated Glass

DOUBLE LAYER LAMINATED SAFETY GLASS

Designing for Safety

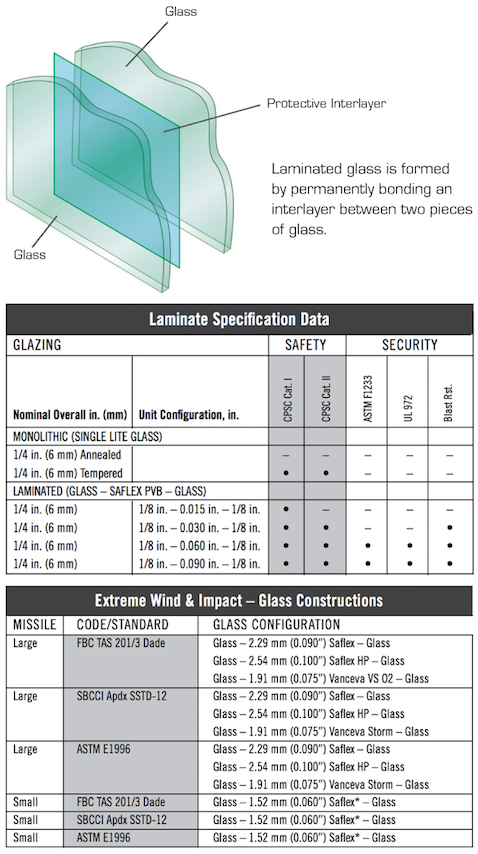

The primary goal of safety glazing is to protect people from accidental glass impact, breakage or fallout. When broken, ordinary glass windows can cause serious injury. Laminated Glass, however, can both prevent bodily injury and protect the building envelope. Safety glazing incorporating PVB protective interlayers in a properly designed and installed system reduces the risk of injury from broken glass. Upon impact, the glass firmly bonds to the interlayer and remains in place, providing protection from dangerous flying or falling glass fragments.

Safety & Standards

RELIANCE HOME Glass is safety glazing material, conforming to the requirements of

CPSC 16FR 1201 Category I Performance

CPSC 16FR 1201 Category II Performance criteria

Underwriters Laboratories’ UL972 Standard for Security Glazing

Class 1 of the ASTM International’s F1233 Security Glazing Test Standard.

Impact Performance

RELIANCE HOME laminated safety glass will resist penetration and will absorb the energy of the impact. The glass will remain intact when broken, with the glass fragments remaining firmly bonded to the interlayer, thus minimising the risk of injuries from sharp edges and falling glass.

Security

If broken, laminated safety glass will remain intact in its frame and will continue to safeguard the building until the glass is replaced. Due to the tough PVB interlayer used, it will continue to provide protection and resistance to entry after the glazing is broken.

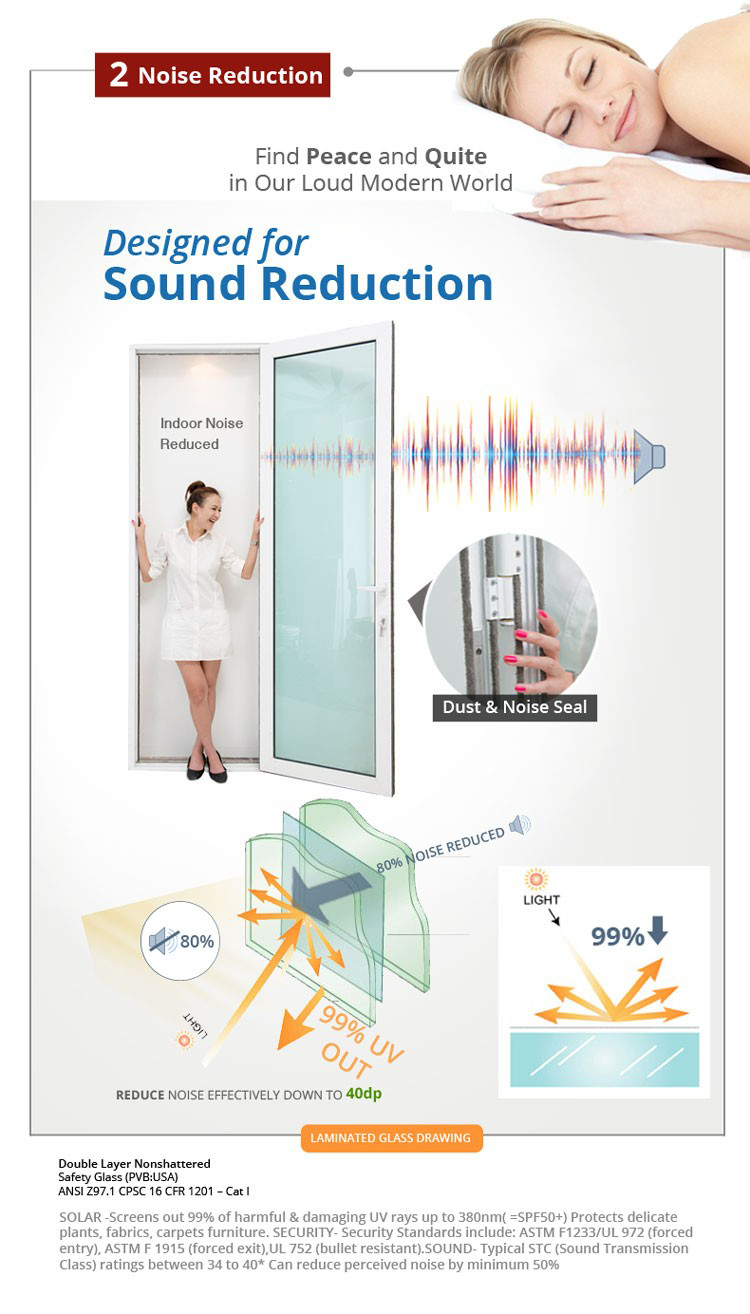

Sound Reduction

The viscoelastic properties of the PVB Interlayer RELIANCE HOME used provide a dampening effect on the transmission of sound, thus reducing unwanted noise.

UV Control

The UV absorbing additive in the PVB interlayer used by RELIANCE HOME can screen out almost all of the sun’s damaging UV rays, thus providing protection against discolouration and damage to fabrics, furniture, wall coverings, furnishings, artworks, etc.

Certification

| Accreditation Body | Certificate Number | Standard Description |

|

BMP 552817 | ASTM C1172-09 Standard Specification for Laminated architectural flat glass. |

|

AR 2502 | Manufacture of heat treated glass, Laminated Glass, insulated glazing units and ceramic frit coated and heat treated safety glass for various industries such as building, marine, furniture and home appliances as accordance to the standard of ISO9001:2008 quality management system. |

|

2871 | Has met all guidelines and requirements for the IGCC/IGMA certification program. The glass is in compliance with ASTM E2190 for seal durability of insulating glass units and passing gas content initial and after weathering (GCIA) certification requirements. |

|

MY-AR 2502 | Manufacturer of heat treated glass, laminated safety glass, insulated glazing units and ceramic frit coated and heat treated glass. |

[twocol_one]

The Facts

Trusted and proven in the most critical applications, PVB can be found in nearly 50 percent of all architectural, safety and security glazing worldwide.Louvre Pyramid,Paris France. Whether protecting people and property from mother nature or from man made threats, PVB interlayer technology brings strength and security to laminated glazing applications.

In safety applications, PVB interlayer provides around the clock protection from windborne debris in areas prone to hurricane and other natural disasters. These products are also highly resistant to the dynamic racking motions of an earthquake helping to maintain the integrity of the building envelope and prevent injury and damage from glass fallout.

[/twocol_one][twocol_one_last]Additional Benefits of Laminated Glass

Acoustic:

Reducing the transmission of unwanted sound into a building’s environment.

Solar:

Filtering more than 99 percent of UV rays, controlling visible light radiation & reducing heat build-up & thermal stress. In addition, PVB interlayers are available in a range of earth-and sky-tone shades, enabling architects to specify Laminated Glass to match industry standard tinted glazing.

Colors:

Interlayers are also avaliable in a range of translucent whites that can be used alone or combined with PVB standard colors to create a broad array of hurricane performance and aesthetic designs

Security Performance

Overhead and Sloped Glazing Laminated Glass made with PVB interlayers can help address the special safety requirements presented by sloped and overhead glazing applications. When laminated glazing is impacted, glass fragments tend to adhere to the interlayer, helping to maintain the system’s integrity. Because of these proven retention characteristics, laminated glass made with PVB protective interlayers meets the performance requirements for sloped and overhead glazing as stated in U.S. and European model building codes.

Designing for Hurricanes

The severe and complex nature of hurricane winds creates special challenges for buildings. When wind-borne debris

breaks glass windows and doors, the building’s protective exterior “envelope” is compromised, allowing strong winds to rush into the structure. These trapped wind forces then exert upward pressure on the roof and outward pressure on exterior walls, and can eventually cause total destruction.

While no single product offers complete protection from hurricanes, typhoons and violent storms, laminated glazing using PVB protective interlayers can be a critical first line of defense. In properly designed systems,

Laminated Glass effectively withstands these forces to help maintain the critical exterior envelope. If broken by impact from wind-borne debris, the glass fragments bond firmly to the protective interlayer, continuing to safeguard building occupants and contents.

Download E-Catalog (PDF Format) as below:-